MOTOCZYSZ

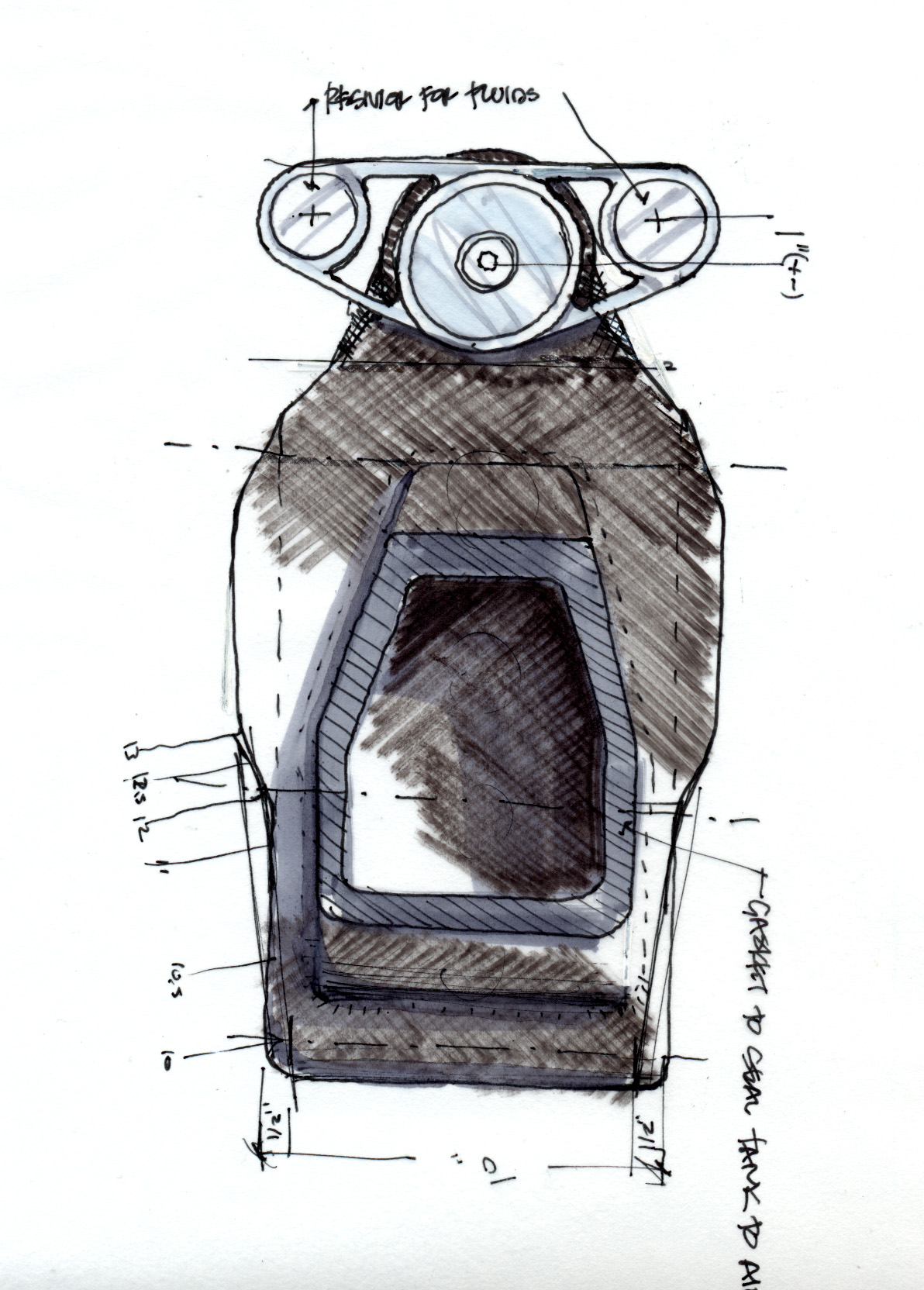

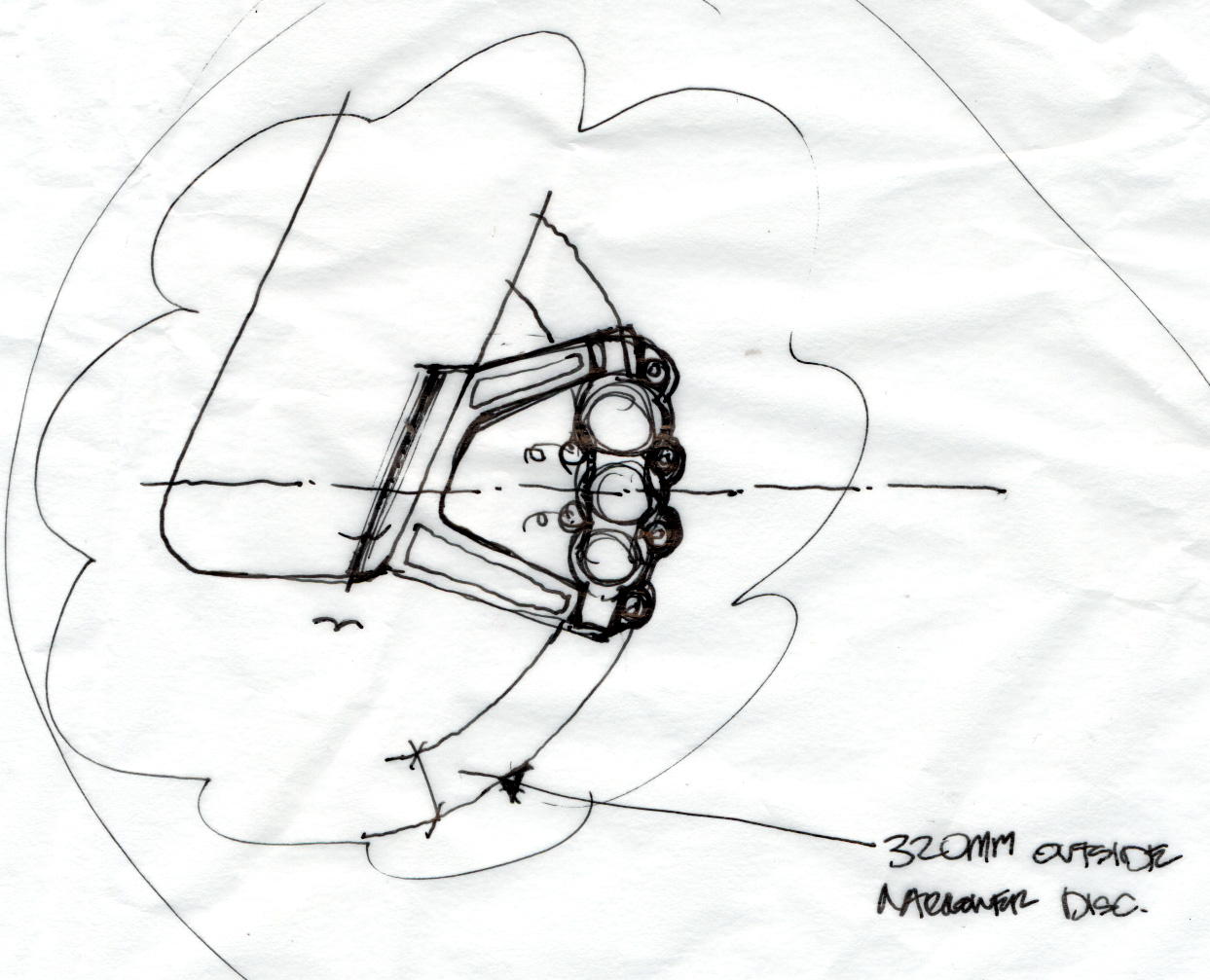

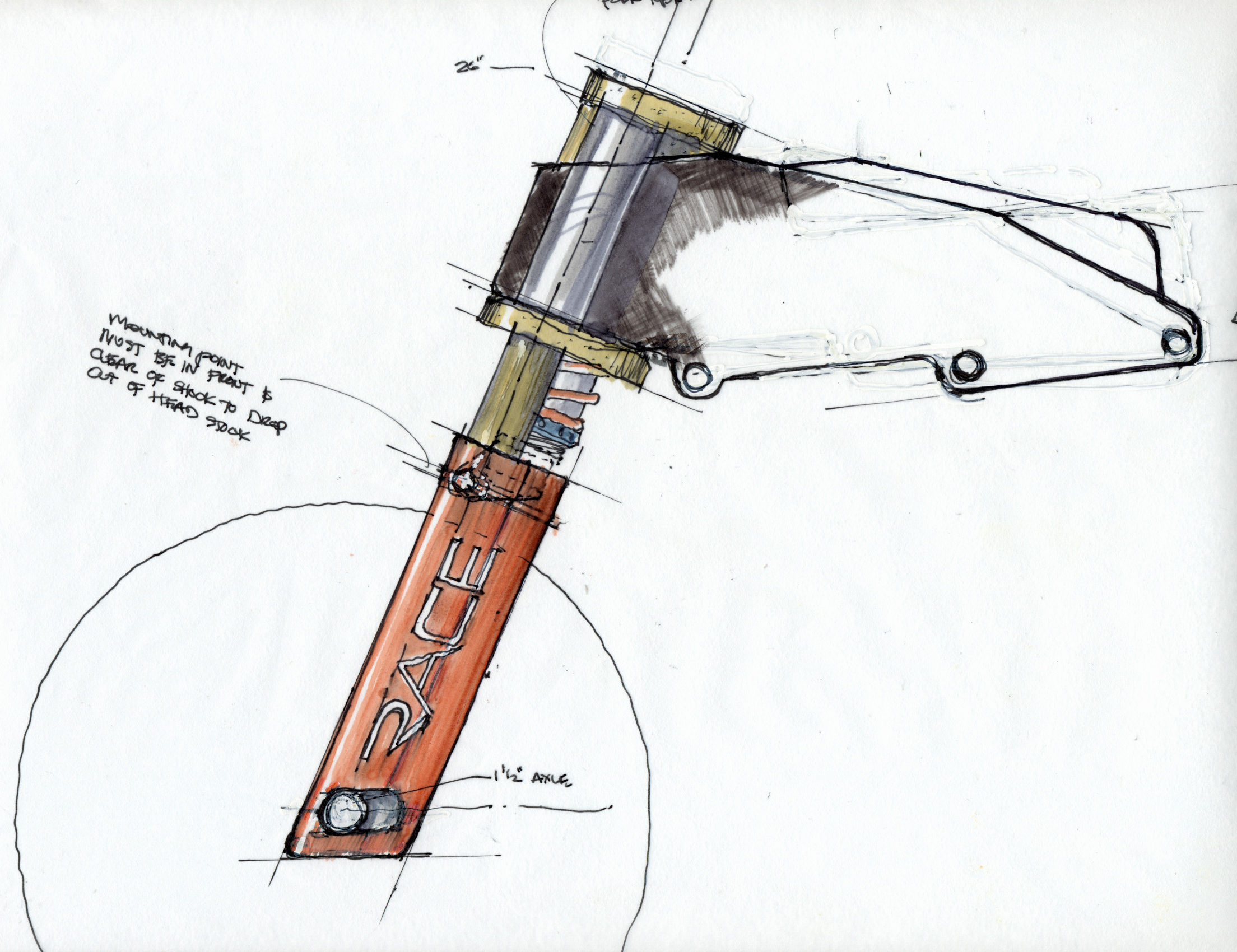

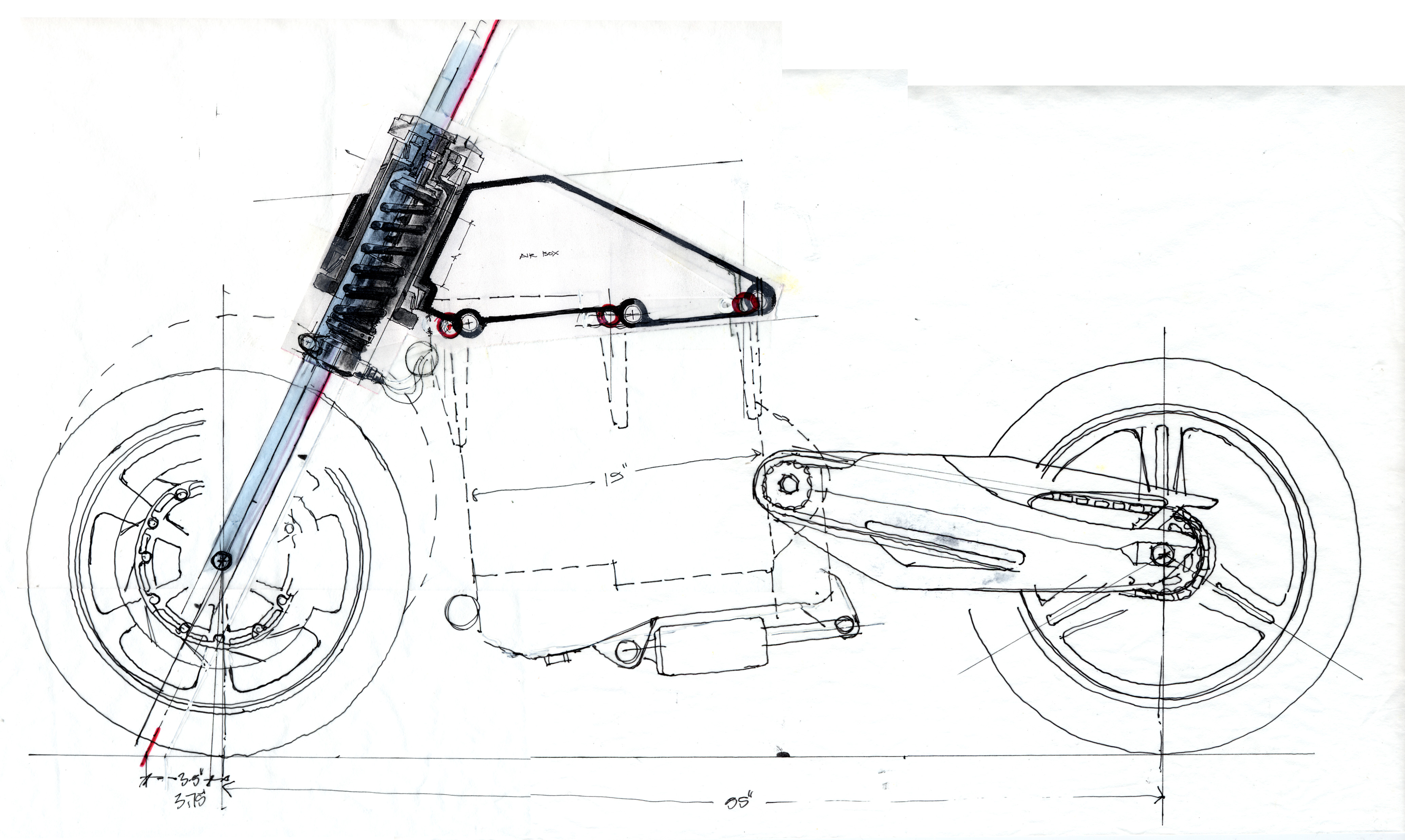

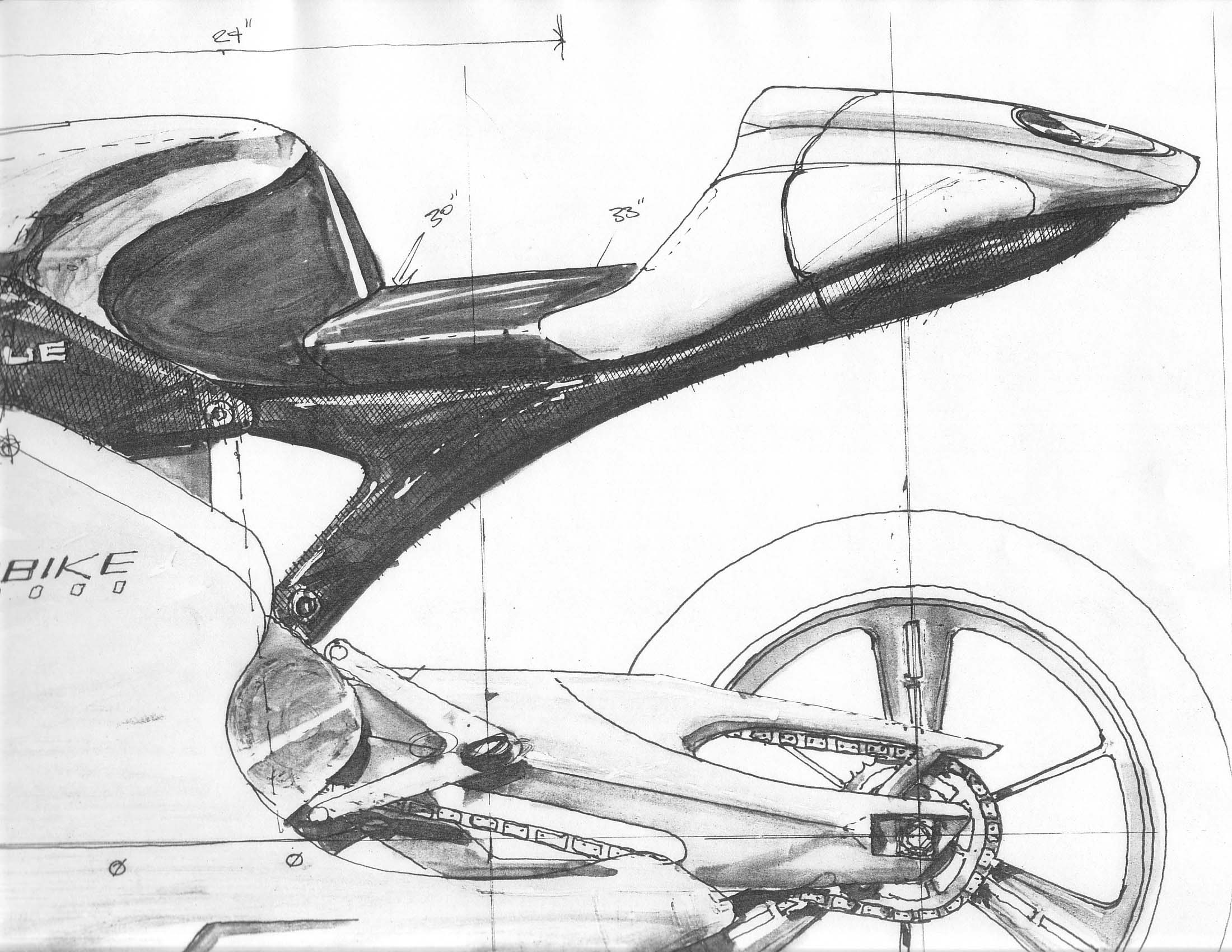

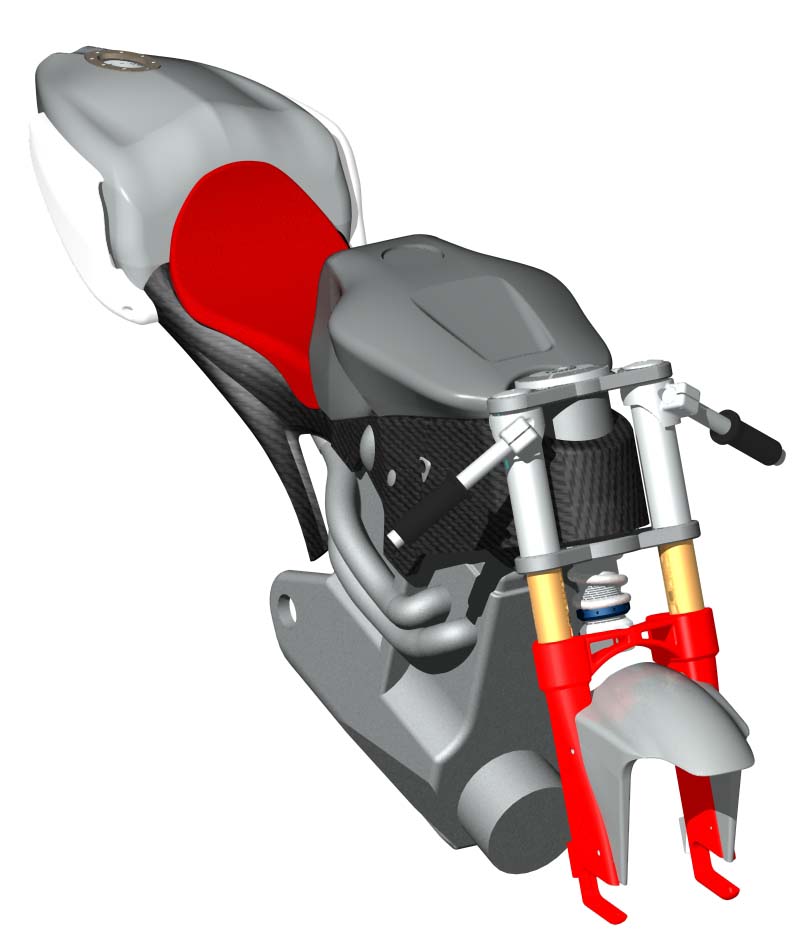

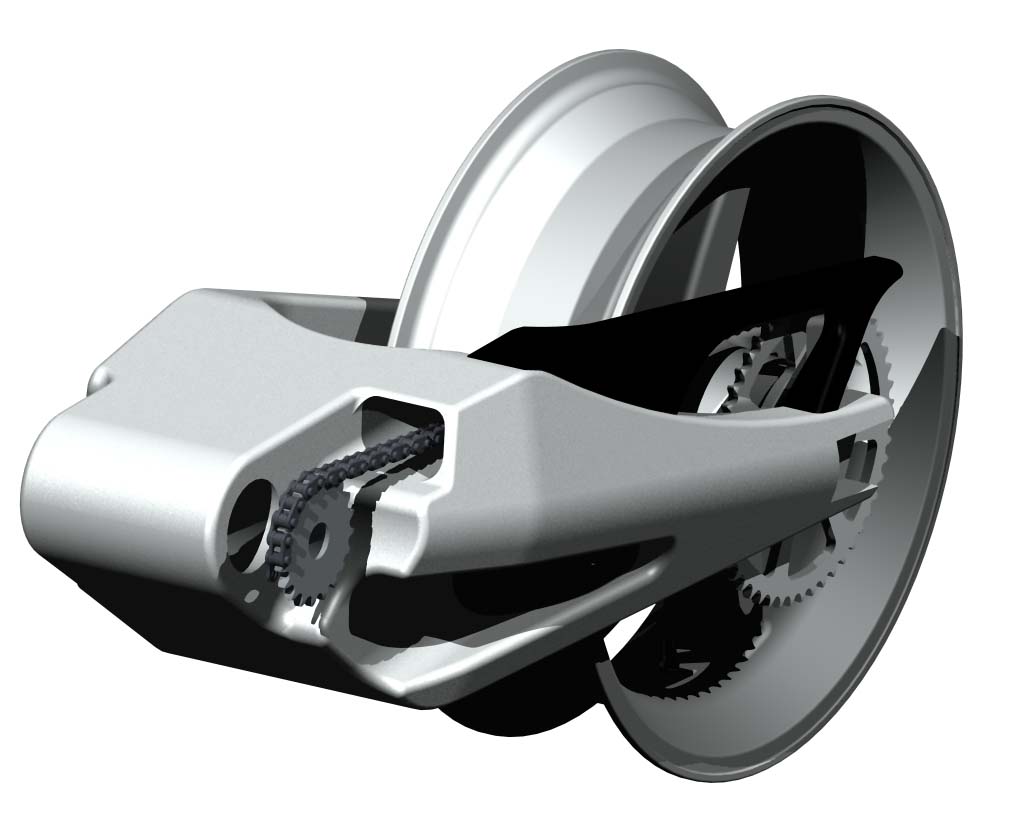

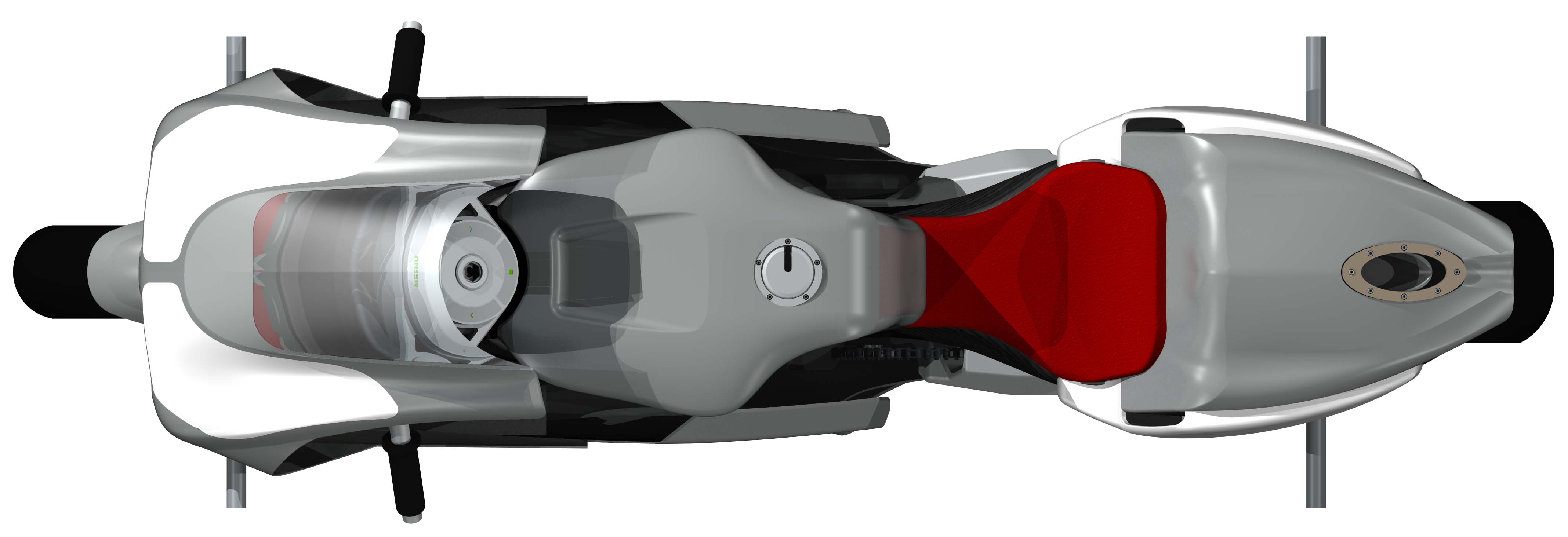

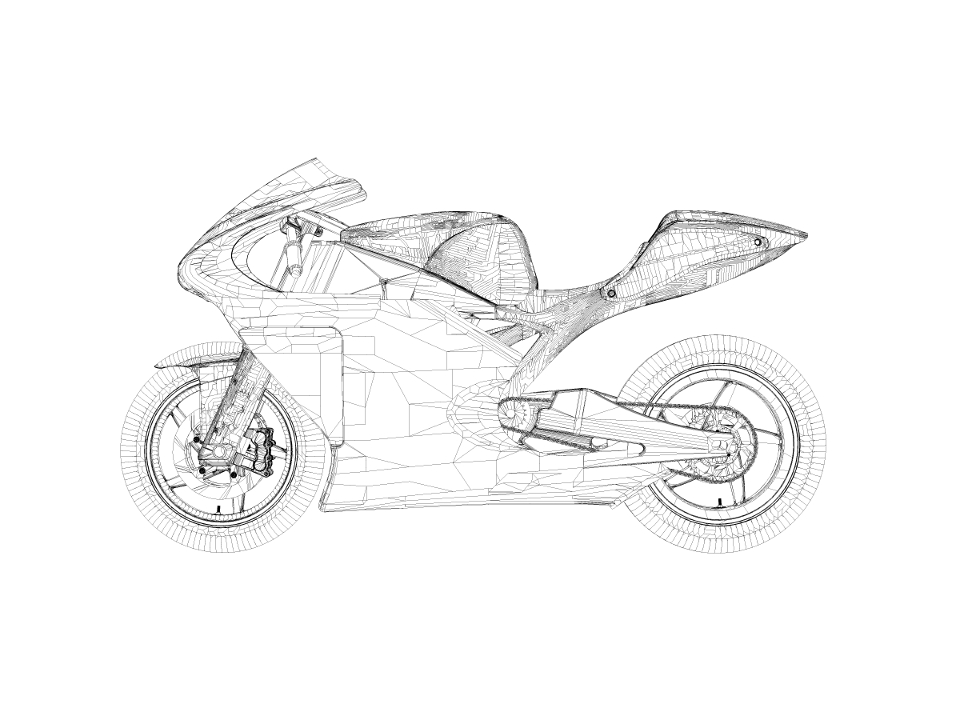

Modeled and rendered a new motorcycle design

Back in Sept of 2002, my boss at Infocus mentioned that he knew of a guy that needed help in modelling a new motorcycle. I met with Michael Czysz at his house, and then proceeded to helped him turn his original hand drawn sketches into 3D models. When I needed help, to help him, I turned to my colleague and mentor Mo Sabri.

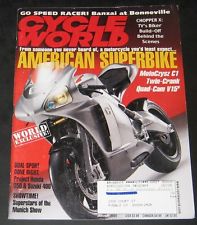

Even though the C1 didn't make it into production Michael was successful, he went on to take the Isle of Man 2 or 3 times on an all electric version of the C1. He made the cover of several publications including CycleWorld January 2005.

It was a very exciting time and an honor to work with Michael. I am deeply saddened by this loss, and post these pictures as a tribute to a friend.

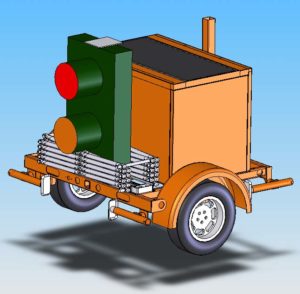

First Call Flagging

Redesign of construction flagging equipment

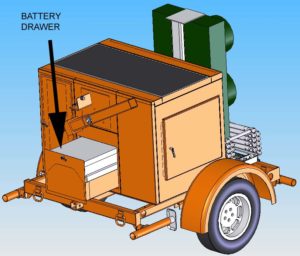

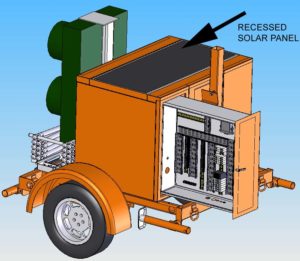

Right around the time I was working on Highway Safety's Night Vision camera, I was introduced to Bret. Bret had a product he was getting manufactured, but since it was a big welded box he wanted to bring down the cost. I used knowledge gained during my time designing RAHU, to modularize the design; making replaceable sheetmetal panels that screwed together.

Work performed:

- Evaluate current design

- Create an intelligent part number system

- Redesign using the new design concept of modularity to streamline manufacturing

- Create drawings to support manufacturing/quote/procurement/inspection

Highway Safety

Packaging of Flir Night Vision camera for consumer use

Back in 2006, the Highway Safety Group wanted to take a FLIR Night Vision camera, and package it for consumer use. There was a secondary use case, to install this design on trains.

I worked with Chad Dornsife to develop the Industrial Design and packaging of the camera. This project went as far as a machined prototype of the lower half, machined by Paul Paine.

Tactical Product Design

TPDUSA

Introduction of the AXR

Back in 2006, while working at Novellus, I got word from a co-worker that there was someone looking for design help, working on guns. I gave him a call, he was stranded in Bend with a non-driveable early series Range Rover. He eventually got back to Portland, after fixing his Range Rover himself, and we met.

It started out with late nights at his dining room table of reverse engineering some smaller parts to create models & drawings (3D & 2D) for him to go machine. It moved onto the main body, where there was measuring, CAD'ing, and measuring again, then changing how we were measuring to re-CAD the features. This measuring and re-CAD'ing happened a lot on that main body, but when all was said and done (on a 9 axis CNC lathe) they were damn nice parts.

To help with organization, and not calling everything bracket 1, bracket 2, etc., I created an intelligent part number system. Which led to creating the full up assembly, but prior to this he had the stock 3D scanned and I had to make sense out of the immense point cloud data to re-create it; the stock alone probably took 100 - 150 hours.

I think he built around 100 devices, and even made the cover and written up in several gun publications. He initially revealed it at the 2007 SHOT Show as an AUG A2 clone.

It was a pleasure working with Kent, and what started out as a working relationship turned into a friendship that's lasted to this day.